Ultraviolet discharge detection

Ultraviolet discharge detection (UV discharge detection) is a non-destructive detection method used to detect corona discharge and surface discharge of high-voltage equipment, which can help maintenance personnel detect insulation problems of equipment early.

Principle of ultraviolet discharge detection:

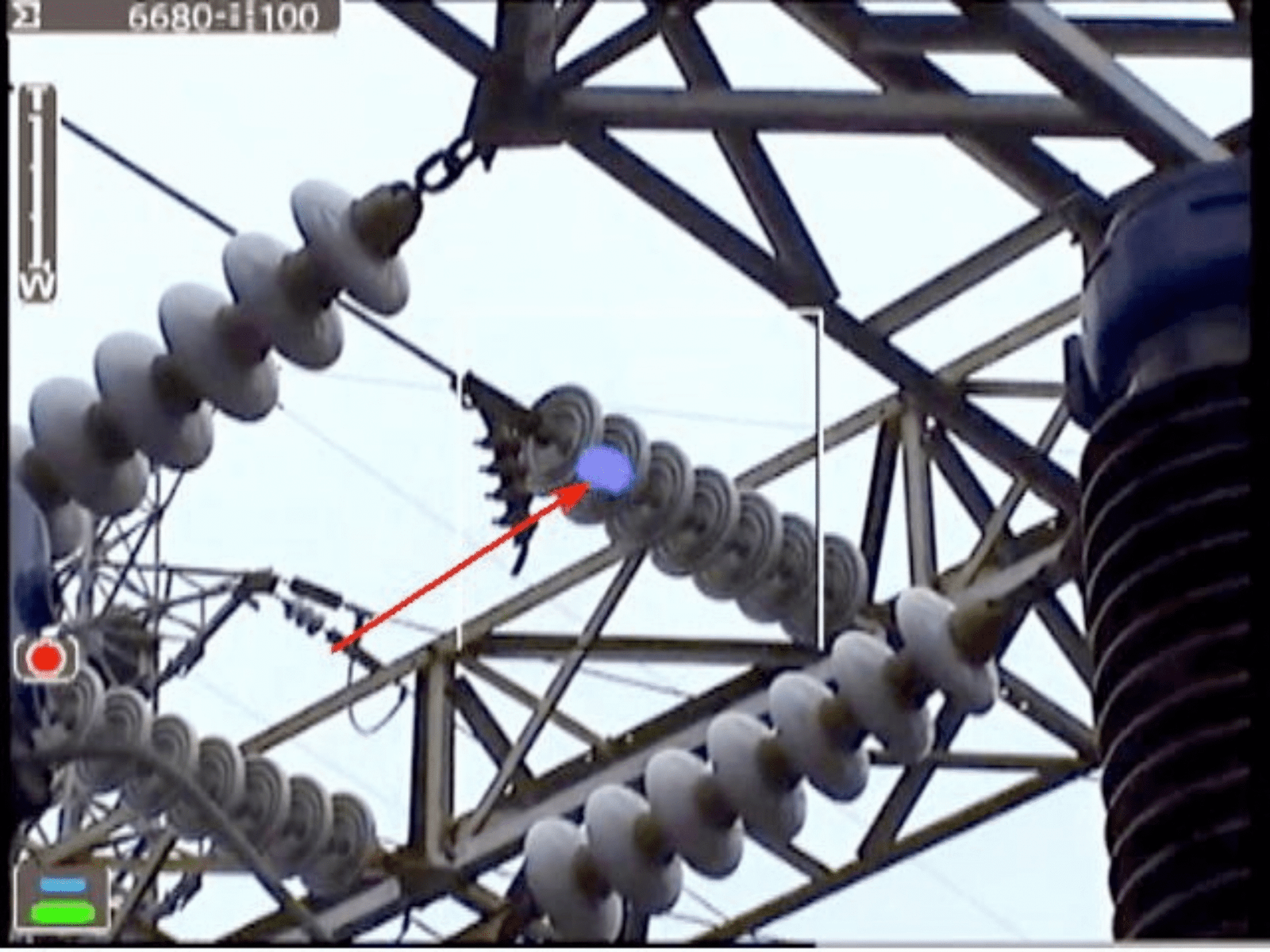

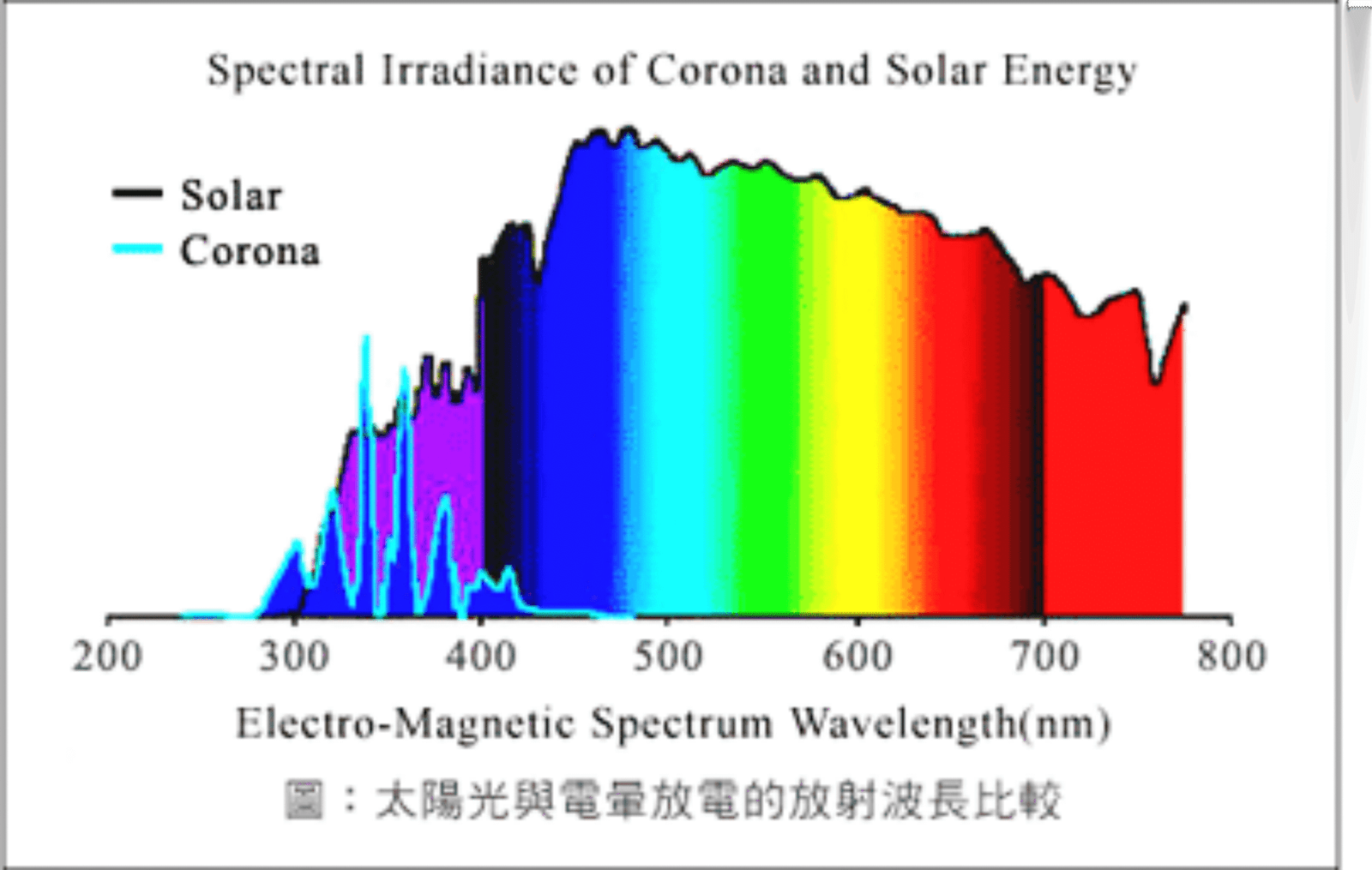

The wavelength of the optical signal generated by the discharge of high-voltage equipment is mainly between 230 and 400nm, which belongs to the ultraviolet range and cannot be directly seen by the human eye.

Ultraviolet instruments can detect these ultraviolet signals and convert them into visible light images, allowing maintenance personnel to clearly see the location and intensity of the discharge.

By analyzing the images of the discharge, the insulation condition of the high-voltage equipment can be determined, and repair or replacement measures can be taken as soon as possible.

Application of ultraviolet discharge detection:

Perform predictive maintenance and testing of power equipment.

Evaluate the effect and cleaning cycle of the anti-fouling measures of the hindrance.

Discover the location of the radio frequency interference source (corona).

Assist in confirming the cause and location of poor insulation.

Monitor flashover discharge problems. Evaluate the construction quality of power equipment after new installation or maintenance.

Assist in the design and production of high-voltage power equipment.

Assist in the maintenance of coil windings (motors, generators, transformers).

Advantages of UV discharge detection:

The discharge site is displayed specifically and clearly to facilitate judgment and maintenance measures.

The cause of the discharge can be determined by the discharge image.

Provide specific image data to facilitate reporting and verification.

Non-contact measurement method, safe and convenient.

The instrument is highly sensitive and can detect initial anomalies early.

Summary: Ultraviolet discharge detection is an important non-destructive detection technology that can help power equipment maintenance personnel detect insulation problems of equipment early and improve the reliability and safety of equipment.